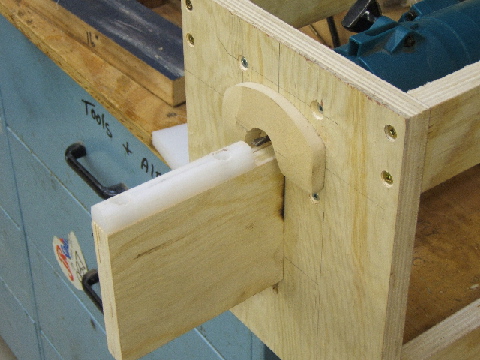

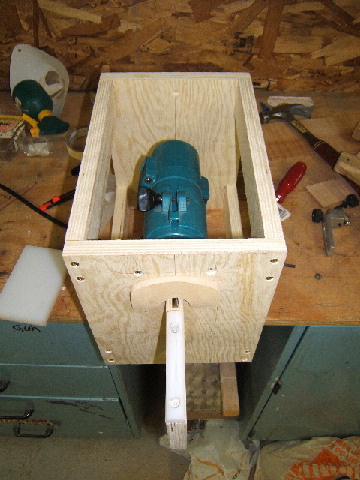

Well, I've never been happy with my binding setup (router and small roller guide). So I decided to make my own like many of you. I based it on the Larrivee/West/guitar jigs design, sort of.

Here are some pics for ya'll. It was very inexpensive to build, like under $5 for materials and $25 for the router bit (spiral down cut). All Canadian, so that is like $1.50 US for the materials and $4.75 US for the bit

.

.

Anyway, hope this can help someone. I do plan on mounting a fine adjustment bolt or screw under the support arm at some point.

The nice thing with this design is that you can realy mount it anywhere. On the bench, in a vice, screw it to the wall. Now I just have to try it out. Wish me luck.